Welcome to ICF Homes Home of The ICF Builders Network

ICF Construction & Technology Articles

The Ultimate ICF System

The choice to use ICF instead of wood frame, etc., is obviously based on the perception that ICF is better. Which ICF system provides the best set of features and benefits that are considered to be valuable for the project? There are only a few types of ICF systems. Each type offers significantly different construction issues and completed results to the owner. Comparisons of the features and benefits of the three types (solid monolithic concrete, waffle grid, and screen grid) are readily available. The comparisons are rarely “apples to apples”, rather based on a variety of different test standards, criteria, and calculations. The actual performance of the ICF’s can be construed as being adequate for constructing energy efficient, durable, disaster resistant, sound concrete walls.There are significant differences in the three types however. The manufacturers offer a myriad of different sales pitches filled with technical information, facts and emotional text. Buyer beware.

Read MoreOptimum Tools

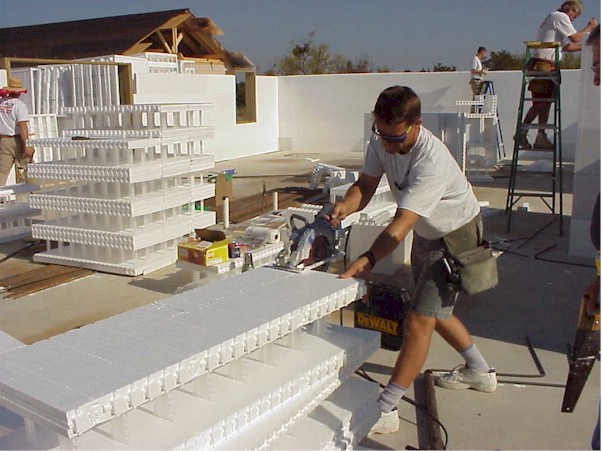

Once you have committed to build with ICF and you have your materials on site or on order, you need to start considering your plan of action on site. The best ICF system can be turned around into one of the worst installations simply by trying to build the walls without the right tools.This list of tools and equipment is includes everything from the basic tools to the optimum setup to handle virtually any ICF install project. The tools and equipment are broken down into several categories. Many of the tools needed for installing ICF’s are not specific to ICF but some items such as a wall alignment scaffold system are somewhat proprietary to ICF. The category delineation has some overlap so your interpretation is invited. Supplies for specific applications such as anchor tunnels etc. are not considered part of the supply list.

Read MoreDispelling ICF Myths

The ICF industry (term used loosely) is rampant with inaccurate information. This is definitely a 'buyer beware' product. Manufacturers, dealers and distributors of the products, installers and builders alike tend to disseminate information that is questionable at best. The toughest part of researching ICF’s is not the gathering of information but the sorting of the information. What is true and factually correct and what is myth or “I believe this to be true, so I will state it as fact” to the customer? Virtually every aspect of ICF is affected by misstated information, whether the discussion is about R-values, structural specifications, cost issues, termites and bugs, application of finishes or waterproofing, electrical, or general installation conversations.

Read MoreWater Management

The first line of defense against mold is preventing the entry of bulk water into building assemblies. If you don’t win that battle, you’ll lose the war. Yes, if you want a mold-free and durable building, controlling indoor relative humidity requires attention as well. But first things first: It all starts with draining water down and out from all roofs, walls and foundations.

Read MoreFeatures & Benefits of ICF

Once a structure is built with ICF there is no comparison to typical frame or block construction. The ICF industry falls into a trap of comparing the benefits and features to typical frame construction, there are no true comparisons between the two. Both ICF and traditional methods of construction perform the same requirements for most structures, but ICF performance criteria are significantly greater than traditional methods.

Read MoreICF Builders Q&A

Click Read More to learn about common ICF building questions such as, what does an ICF Home look like when it is finished? How tall can you build with an ICF Building System? Will termites eat the EPS Foam?

Read MoreInsulating Concrete Forms

Why Build With ICF?

- Safety & Health

- Energy Performance

- Flexibility in Design

- Comfort

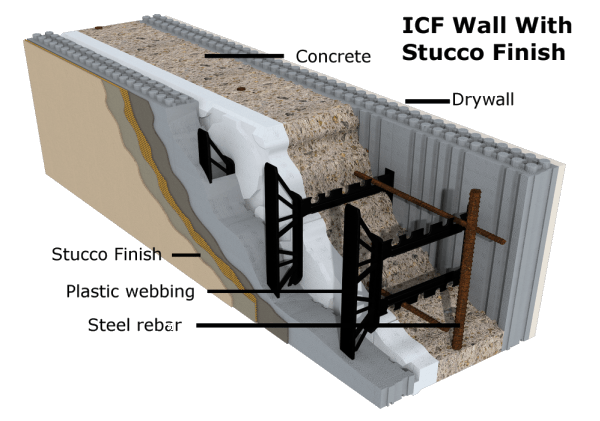

Insulated Concrete Forms (or ICFs) are forms or molds that have built-in insulation for accepting reinforced concrete. The first patent application for an ICF was registered in the late 1960’s. Since then, and particularly in the last 4 years, ICFs have been fast-becoming the mainstream preferred building product worldwide for all of the right reasons. These large, hollow blocks are stacked right off of the truck and filled with reinforcing bar and concrete. The end result leaves you with a high-performing wall that is structurally sound, insulated, strapped, has a vapor barrier and is ready to accept final exterior and interior finishes.